The battery thermal management system of a vehicle takes a systematic and holistic approach to the relationship between heat, the engine, and the vehicle as a whole, controlling and optimizing heat transmission through a variety of techniques. The system can automatically adjust the cooling intensity based on driving and environmental conditions to ensure that the cooled object operates within an optimal temperature range, thereby optimizing the overall vehicle's environmental performance and energy-saving effect, as well as improving operational safety and driving comfort.

Guchen plays a key role in delivering innovative battery thermal management solutions that meet these complex needs.

Thermal management strategy for conventional fuel vehicles

The thermal management strategy for conventional fuel vehicles generally divides its functions into the powertrain thermal system and the cabin thermal system. Its main circulation systems include

Engine cooling circulation: relatively simple, mainly comprising the engine, radiator, thermostat and water pump.

Air conditioning cycle: The key components include the condenser, compressor and expansion valve.

Charge-air cooling system: This system increases the intake air volume of the engine to improve power performance. Since the temperature of the pressurized air is high, the intake air temperature must be reduced by a charge-air cooler. The main components include a supercharger and charge-air cooler.

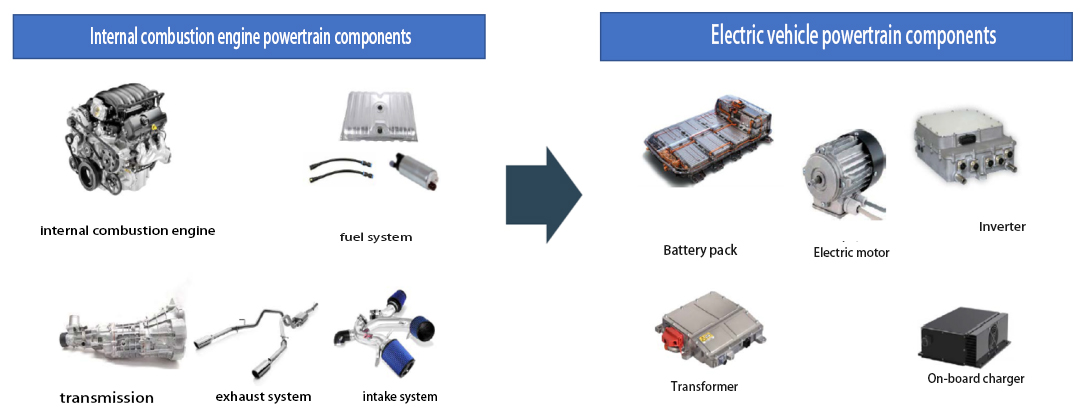

The battery thermal mamagement system for new energy vehicles adds the cooling requirements of components such as the battery, motor and control system. It is equivalent to adding the thermal management of the “three electric systems” (battery, motor and electronic control system) to the thermal management of traditional vehicles, and the requirements for BTMS strategies are higher.

The BTMS system for new energy vehicles mainly includes the following three parts:

The air conditioning system of traditional fuel vehicles is driven by the engine to drive the compressor, while new energy vehicles use an

electric compressor.

In fuel vehicles, the air conditioning and engine are relatively independent, while the cooling systems of the three electric batteries in new energy vehicles are closely

linked, and the battery cooling system usually shares the cold source with the air conditioning system.

Usually, a larger power compressor is selected for sharing to meet the cooling needs of the air conditioning and battery.The battery does not need too much cooling when the vehicle is just starting, thus more power can be directed to the air conditioning at this moment to rapidly lower the temperature inside the car. This design not only guarantees sensi

ble use of resources to enable the vehicle to run effectively under various operating situations, but also increases the cooling efficiency of the air conditioning.

In fuel vehicles, the heating process relies on the engine as a heat source, using a water pump to drive the water circulation. In contrast, new energy vehicles primarily utilize electric heating. A more energy-efficient solution is the adoption of heat pump air conditioning systems, which enhance overall energy management and efficiency.

- Battery thermal management system:

The ideal running temperature range for power batteries is 20–30°C according to battery thermal management systems. Low temperatures may lower battery capacity and cause poor charging and discharging performance; high temperatures will degrade the cycle life of the battery and even cause safety concerns like explosions.

A battery pack is formed by several battery cells coupled in both series and parallel; the heat produced while charging and discharging will influence each other. To thus guarantee that the battery pack stays within a reasonable temperature range, a sophisticated battery thermal management system is needed.

- Motor and electronic control system thermal management:

The motors and electronic control systems of new energy vehicles require high heat dissipation during operation and usually need active cooling. These components often only require cooling devices.

Summary

The EV Battery Thermal Management System needs to meet a variety of requirements, such as cabin air conditioning (cooling, heating, defogging, etc.), battery pack temperature control, and heat dissipation of motors and controllers. With the continuous improvement of the requirements for comprehensive vehicle energy management, the BTMS system is gradually pursuing higher compactness and lightweight design

If you are struggling with thermal management issues, the Guchen brand is your best choice. We have professional customized EV BTMS solutions. Whether it is in the field of new energy vehicles, heavy trucks or construction machinery, we can effectively solve your thermal management problems, ensure stable operation of equipment, improve efficiency and reduce costs. Choose Guchen and let us work together to usher in a new era of worry-free thermal management.