Bus air conditioner catalogue

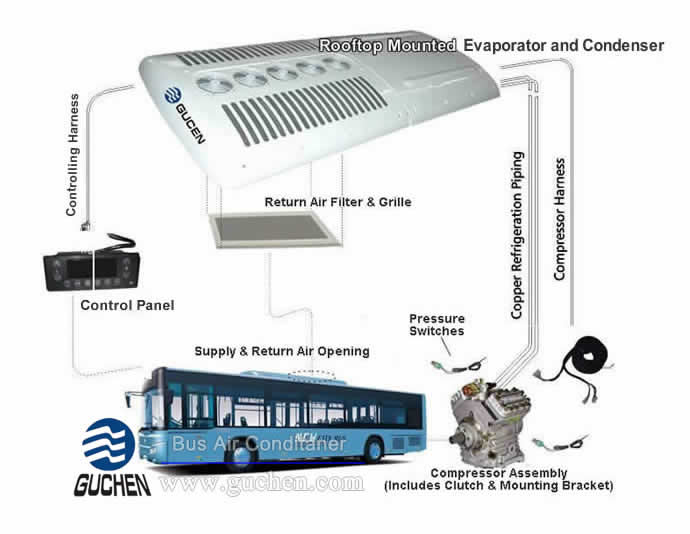

The bus air conditioning system mainly consists of the condenser, evaporator, compressor, magnetic clutch, alternator, fresh air device, blower, fan, retnrn air grille, control panel, pipeline system and electric-controlled system.

The reservoir, filter direr, sight glass, cut-off valve, expansion valve, and fresh air device are located in the interior of the evaporator.

The compressor is mounted on the side of the engine, and the climate control panel of the

bus air conditioning system has its own starting system, which is located beside of the instrument board.

The rooftop mounted evaporator assembly of

bus air conditioning are adopting the SMC housing to protect its components and remain a good insulation performance (Most bus air conditioning system’s evaporator use the traditional FRP housing, but

Guchen Industry adopts the SMC and LFT housing materials which is lighter, higher strength and more environmental).

The condenser is mainly divided into new design Multi-flow-condenser (micro channel condenser) and traditional copper and fin condenser, the condenser fan blows the air through the condenser coil, in order to aide the heat dissipation better.

Working Principle of Bus Air Conditioning System

● When you press the ON/OFF button on control panel of bus air conditioning in the driver’s cabin, relying on an inter connecting electrical system, the compressor is driven by the

electromagnetic clutch via the belt which connected to driven pulley of engine, then the compressor circulates refrigerant through the interal connecting hoses system.

● Refrigerant, as gas, we use the R134a refrigerant in our bus a/c system, together with the heat from the passenger compartment, which is pumped by the

compressor to the high-temperature high-pressure gas, and entering the condenser coil via the high-pressure air-conditioning pipeline.

● Since the temperature of refrigerant entering condenser is higher than outside temperature, condenser fans cooling the condenser coil, and taking away a lot of heat energy which contains refrigerant existing as a hot gas.

● The refrigerant undergoes the liquefied exothermic reaction, from high-temperature high pressure gas to medium-temperature, high-pressure liquid.

● Now, the refrigerant exists as a cool liquid, passes the reservoir, cut-off valve (will decrease the waste of refrigerant while repair and maintain the bus air conditioning sysem, and bring the convenience for aftersale engineers.), and entires filter drier which removing moisture and foreign materials, containing the filter, desiccant. Then the filtered refrigerant enters the sight glass, a device which can visual inspection of the refrigerant like water.

● Then cooled liquid refrigerant flows into the evaporator through expansion valve, which controls the volume of refrigerant into the evaporator coil and decrease the pressure of refrigerant

● Evaporator absorb the hot air energy form passenger compartment through a return air grille device which includes an fresh air system which removes particulate matter without influencing cooling effect, then the

evaporator blower blows the cleaned and cooled air into the passenger compartment through the evaporator coil

● The refrigerant under a change-of-state from a liquid to a gas, and a corresponding change of pressure from high to low, which called evaporation.

● During evaporation, due to its throttling effect, the cool liquid through the expansion valve becomes gas, and the gaseous refrigerant absorbs a lot of heat energy, containing the passenger compartment hot air, so as to achieve the purpose of the cooing.

● Warming air passing the evaporator coil, due to cooling effect, moisture condensation, then it is collected and discharged to the outside of the bus.

● The hot gas in passenger compartment is then suctioned by the compressor, where it is compressed and refrigeration cycle repeats.

Details of Bus Air Conditioner: