-

All-electric Bus Air Conditioner

-

Traditional Bus Air Conditioner

-

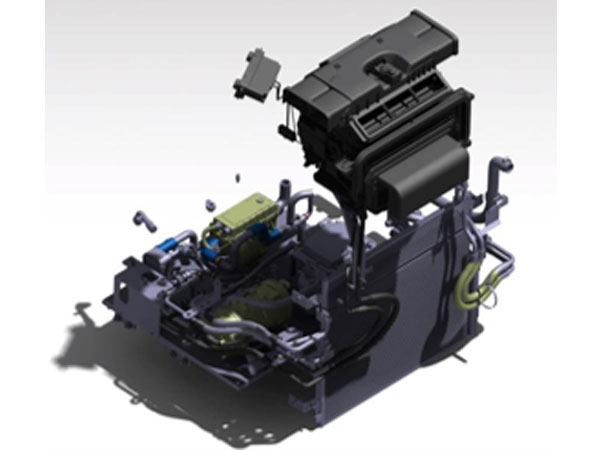

Battery Thermal Management System (BTMS)

-

Parking Truck Air Conditioner

-

RV Air Conditioners

-

Van Air Conditioner

-

Transport Refrigeration Units

-

Bus A/C Parts

-

Spare Parts

-

-

-

-

-

-

-

-

-

A battery thermal management system typically includes temperature sensors, control systems, heat dissipation systems, and cooling systems. The temperature sensor monitors the battery temperature, while the control system adjusts the heat dissipation and cooling systems based on this data, ensuring optimal battery temperature regulation.

What kind of vehicles needs a battery thermal management system?

Heavy trucks, light trucks, construction vehicles, agricultural vehicles, and transport vehicles.

Heavy-duty trucks and engineering vehicles have a large load capacity and are mostly used in engineering construction and overweight cargo transportation. Therefore, the battery load of heavy trucks and engineering vehicles will be very large, and the battery has overheated. BTMS can help the vehicle battery to cool down and ensure that the battery operates at an optimal temperature, thereby ensuring the safety of the vehicle.

Light trucks, agricultural vehicles, and transport vehicles are characterized by frequent use and long working hours. The battery is prone to overheating problems during long-term work and operation, and safety accidents are prone to occur during long-term use. In order to ensure the safety of personnel, vehicles, and goods, it is necessary to monitor and manage batteries in real-time. The main function of battery thermal management is to monitor the status of the vehicle battery, so as to make the best choice to optimize the battery temperature, thereby prolonging the battery life and battery safety.

Guchen has a stand-alone battery thermal management system and an integrated battery thermal management system.

The independent thermal management system can be applied to buses and heavy trucks with large spaces due to its large system size and inseparability. In order to meet the needs of light truck vehicles, we have developed an integrated thermal management system suitable for light trucks with small spaces. Our thermal management systems have been developed to suit most bus and truck applications.

What are the components of a battery management system?

▶ Compressor module, including compressor, gas-liquid separator, expansion valve, battery panel replacement, and high and low-pressure controller;

▶ Cooling module, including the condenser, motor radiator, and cooling fan;

▶ HVAC air conditioning box, including blower, evaporative core, and warm core;

▶ Piping parts, including media piping and plumbing piping;

▶ Control panel.

Advantages of Guchen Truck Battery Thermal Management System

★ The electronic expansion valve is used to adjust the refrigerant flow rate of the system. The two systems can realize three modes of independent operation and joint operation. The side that does not need refrigeration can close the corresponding electronic expansion valve/solenoid valve;

★ A temperature and pressure sensor is added behind the evaporator, coupled with the cooling logic on the air conditioner side and the water temperature control scheme on the battery side, and synchronously adjusts the openings of electronic expansion valve 1 and electronic expansion valve 2, effectively Solving the problem of uneven cooling capacity distribution and at the same time Avoid temperature fluctuations in the car and on the battery side, which has obvious advantages in car comfort and battery temperature control;

★ Through the PID control technology, the speed of the compressor and the condensing fan can be precisely adjusted to realize the energy saving of the product;

★ Compared with the independent battery thermal management system, the integrated system can effectively reduce the weight and cost of the product while meeting the product requirements;

★ Multiple protections such as temperature, pressure, current, and voltage are added to the system, which can identify system operation risks in advance and effectively improve product operation reliability and safety;

★ The unit adopts CAN communication network, and the operating data of the unit can be uploaded to the instrument in real time, and remote fault diagnosis and treatment can be realized through intelligent network connection, which is convenient for detecting the operating status of the unit it and troubleshooting after-sales.

In short, the battery thermal management system ensures that the battery can maintain a stable temperature range during operation through steps such as temperature measurement, temperature analysis, temperature control, and temperature monitoring, thereby improving the working efficiency and life of the battery.