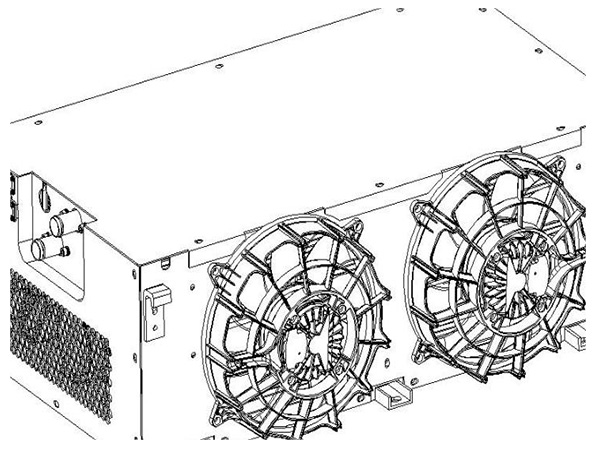

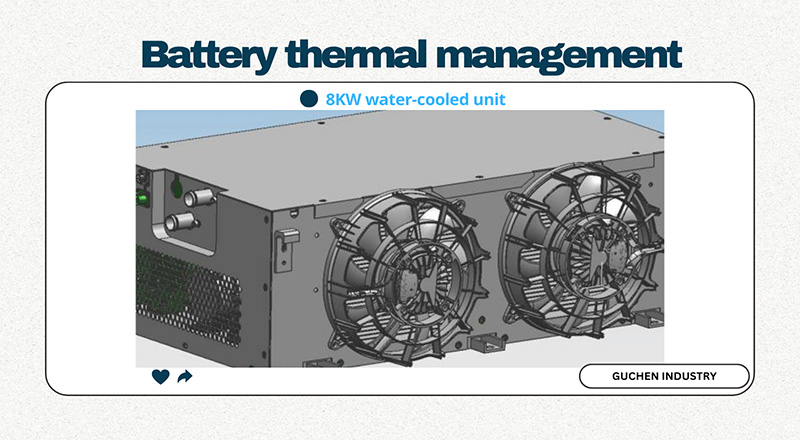

8kW Water Cooling Unit for Battery Thermal Management

The 8kW water cooling unit for battery thermal management is an independent, modular system specifically developed for power battery packs requiring up to 8kW of cooling capacity. This versatile unit can be applied to various new energy vehicles, including heavy trucks and large buses, given adequate space.

Key Features:

- Modular Independence: Designed as a standalone unit for easy integration across different vehicle models.

- 8kW Cooling Capacity: Tailored to meet the cooling demands of power battery packs needing up to 8kW of cooling.

- Liquid Cooling:This method offers higher heat dissipation efficiency, allowing the heat generated by the device to be carried away faster. Liquid cooling technology reduces the battery's temperature more efficiently, improving its performance and lifespan. Compared to the noise generated by a fan, the noise of liquid cooling is much lower.

GUCHEN This water cooling unit for battery thermal management is engineered to enhance the reliability, performance, and longevity of new energy vehicles by maintaining optimal battery temperatures.

See Guchen Battery Thermal Management System catalogue here.